Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

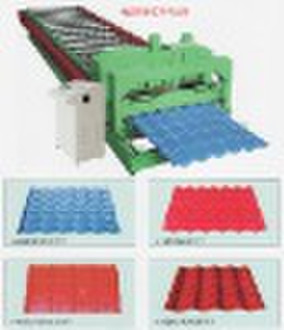

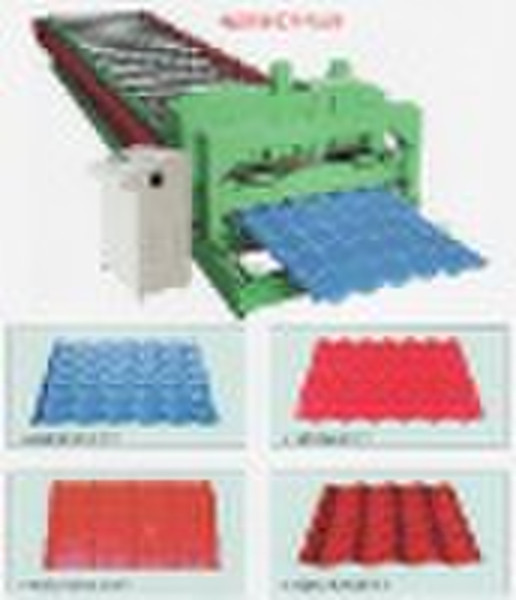

YX 1100 Glazed tile roll forming machine

Jessie Zhang

Contact person

Basic Information

1100Glazed Tile Roll Forming Machine Our roll forming machine can produce different kinds of steel panel tiles for roof and wall. Our products are widely used in various fields: industrial factory, civilian building, warehouse, easy steel building, roof board, interior wall board and external wall board, decoration and have features such as nice appearance and durable. Main Technical parameter: Type1100 Arc Bias Glazed Tile Roll Forming MachineMaterial Speccolored steel sheet, galvanized steel sheetMain motor power5.5kwForming speed6-8m/minDiameter of roller80 millimeterThickness of Coil Sheet0.3-0.8 millimeterThe width of the colored sheet1250 millimeterThe effective of steel sheet1100 millimeterHydraulic station pressure3 kwHydraulic pressure10 - 12MpaTotal Weight 3.0tonVoltage380 voltRoll stand12 groupsPLCComputer adopt PLC, Mitsubishi FX-IS seriesSize length*width*high5.6m*1.2m*1.2mRoller material:high grade No.45 forged steel, plated hardchrome on the surface of roller with thickness 0.05 millimeterFrequency converterMitsubishiRotary EncoderOMRONMaterial of cutterCr12We also can design and manufacture according to customer’s requirement. Technical process:Manual decoiler---feed with guide---roll forming---press step---cut with fixed length---output with table We have developed more than 10 series of Steel Roll Forming Machines which can meet the requirements of all steel constructions, such as wall & roof sheet forming machine, color steel tile forming machine, C & Z shape purlin forming machineand floor decking sheet forming machineas well as production line for all kinds of sandwich panels, curving machine for roof sheets. We also supply production lines of guardrail sheet for expressway, shutter doors, garages doors and downpipe. Besides, we devoted ourselves to the research & development of various kinds of other products related to steel structure, such as hydraulic press brake machine, shearing machine, slitting machine, lift machine, gas cutting machine, drilling machine, etc.

Delivery terms and packaging

Packaging Detail: The machine nake loaded into container, covered with plastic film, spare parts in wooden box or as your requires. Delivery Detail: Witnin 30 working days upon receiving the advence payment.

Port: TianJin port

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: